Energy & Critical Metals

UNSW team proposes hard carbons from automotive shredder residue as anode material for sodium-ion batteries

Researchers from UNSW Sydney (Australia) report in an open-access paper in the Journal of Power Sources on the use of hard carbons derived from automotive…

Researchers from UNSW Sydney (Australia) report in an open-access paper in the Journal of Power Sources on the use of hard carbons derived from automotive shredder residue (ASR) as a suitable anode electroactive material for sodium-ion batteries (NIBs).

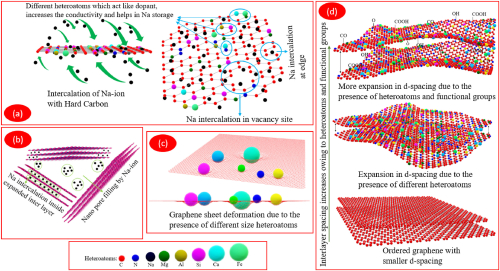

Limitation of graphite as anode material in NIB has paved the way for other carbonaceous materials to be used as anode material in NIBs. For instance, various kind of non-graphitic carbonaceous materials like hard carbons, soft carbons, and amorphous carbons have been tested as anode material in NIBs. Among all these carbonaceous materials, hard carbons have grasped the special attention due to their high thermal stability, low cost, and availability. Hard carbons are consisted of randomly oriented microdomains and loosely stacked layer of graphene with larger interlayer spacing than the graphite. In hard carbons, the Na+ ion can easily store in expanded graphite layer, defects at the graphene plane, and nanovoids in between randomly stacked graphite layer.

The large interlayer spacing of hard carbons acts as buffer during Na+ ion insertion, because it helps to avoid the volume changes caused by Na+ ion insertion. On the contrary soft carbons have smaller amount of nanovoids and lesser interlayer spacing in comparison with hard carbons. Though the soft carbons contain some amount of turbostratic carbon, the Na+ ion storage in soft carbon is lower than the hard carbon.

The situation is much worse for graphite. The orderly stacked graphene layer and the absence of nanovoids allow graphite to store very few amount of Na+ ions at the graphene edges. The unique microstructure of hard carbons facilitates the sodiation/desodiation process in NIB during electrochemical operation. Recent studies on hard carbons say that most of the hard carbons provide specific capacities between 200mAh/g to 300mAh/g as anode material in NIB.

—Sarkar et al.

Around 50 million tons of end-of-life vehicles (ELVs) are generated per year. ELVs usually contain 70–75% ferrous metal, 5% non-ferrous metal, and 20–25% automotive shredder residue (ASR). It is projected that by the end of 2030 the amount ASR will reach 9 million ton, the researchers said. ASR usually contains plastic (35–55%), rubber (10–20%), wood (15–40%), and textile and other materials (5–15%).

For the study, three carbon materials were synthesised from ASR at 700 °C, 900 °C, and 1100 °C.

Prepared via a single-step selective thermal transformation, the ASR-derived hard carbons contain defects, heteroatoms, nanopores, and ordered carbon zones with expanded interlayer spacing. Among all the hard carbons, hard carbon synthesized at 1100 ˚C showed better electrochemical performance due to its improved structural and morphological properties.

The electrochemical study showed that hard carbon synthesized at 1100 ˚C provides initial reversible capacity of 434 mAh/g at a current density of 10 mA/g with a capacity retention of 53% after 100 cycles.

Visual representation of Na+ ions storage in hard carbons: (a) Na+ ions storage at different defect sites; (b) Na+ ions storage in nano pore and between two expanded graphene layers; (c) Deformation of graphene layer due to the presence of different size heteroatoms; (d) Enlarging in interlayer spacing due to the presence of heteroatoms and functional groups. Sarkar et al.

Resources

-

Montajar Sarkar, Rumana Hossain, Veena Sahajwalla (2023)

“Hard carbons from automotive shredder residue (ASR) as potential anode active material for sodium ion battery,” Journal of Power Sources,

Volume 584, doi: 10.1016/j.jpowsour.2023.233577

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…