Energy & Critical Metals

Altech cracks the silicon code: DFS outlines attractive IRR of 34% for higher energy EV batteries

While Tesla is trumpeting the need for silicon in battery anodes to increase lithium-ion energy density, Altech believes it has … Read More

The post…

- Altech has received the ‘exceptional’ results from a DFS conducted for an 8,000tpa silicon plant in Germany

- ATC’s pilot plant construction is in the final stages for product qualification

- Non-disclosure agreements (NDAs) have been executed with two German and two US automakers

Special Report: While Tesla is trumpeting the need for silicon in battery anodes to increase lithium-ion energy density, Altech believes it has already cracked the “silicon code” with results from a Definitive Feasibility Study (DFS) highlighting “outstanding” economics.

In-house research and development has led to Altech (ASX:ATC) cracking the “silicon code” with its Silumina Anodes product, which incorporates High Purity Alumina (HPA) coated silicon and graphite into the anode of lithium-ion batteries.

The beauty of it is its ability to achieve 30% higher energy capacity with the addition of silicon into the anodes, resulting in a battery that has higher energy retention capacity by volume and weight.

This means smaller, lighter batteries for the EV market, paving the way for increased lithium-ion battery energy density, battery lifespan and reduced first-cycle lithium loss.

Breakthrough Silumina anodes product

To achieve its breakthrough, ATC successfully coated silicon particles with high-purity nano layer of alumina, producing the “Silumina anodes” product.

ATC’s alumina coating technology resolves the expansion defragmentation, as well as curbing the significant first-cycle loss associated with silicon.

From laboratory testing, the previously unresolved impediments for using silicon in lithium-ion battery anodes which are: silicon particle swelling; prohibitive first-cycle-capacity-loss of up to 50%; and rapid battery degradation, appeared to have been substantially overcome during Altech’s testing of the composite graphite/silicon batteries.

This product, manufactured exclusively under license from Altech, is strategically aimed at meeting the escalating demand in the European and US electric vehicle and grid storage battery market.

DFS… the numbers explained

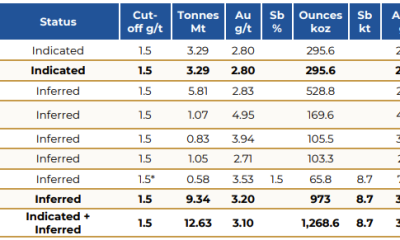

ATC has been focused on completing a DFS for an 8,000tpa (120GWh) alumina coated metallurgical silicon plant planned for Saxony, Germany.

This facility, spearheaded by Altech Industries Germany GmbH (AIG) with ownership split of 75% Altech and 25% Frankfurt stock exchange listed Altech Advanced Materials AG (AAM), is set to produce ATC’s silumina anodes.

With a capital investment of €112 million, Altech’s DFS projects a net present value of €684 million with net cash of €105 million per annum generated from operations.

The internal rate of return (IRR) is estimated at 34%, with investment capital paid back in 2.4 years and total revenue estimated at €328 million per annum.

The major capital cost component for the project is the construction of the silumina anodes facility and the associated site infrastructure, such as the administration building, maintenance workshop, and on-site QA laboratory.

ATC says the engineering design and cost estimate for the battery materials coating facility has been based on the process design and equipment required to process 8,000tpa of anode materials and utilises equipment design and building layouts specifically developed during the DFS.

Pilot plant

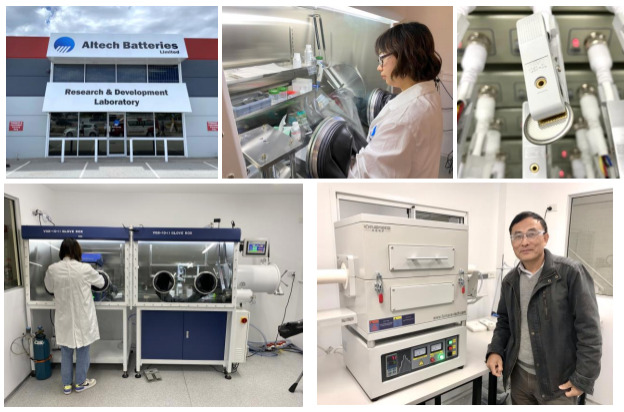

As the company accelerates its efforts to introduce its patented technology to the market, it is in the final stages of construction of a pilot plant in an existing building in Dock3 at Schwarze Pumpe.

The pilot plant, which is already fully commissioned, is designed to produce 120kg per day of coated battery anode material, which will be made available to selected European and US battery manufacturers and auto-makers.

Already, the company says the product has generated significant interest in the market with NDAs executed with two German automakers, two US automakers, one US battery materials supply company and one European battery maker.

ATC says these automakers have requested commercial samples for their testing and qualification procedures.

This article was developed in collaboration with Altech Batteries, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

The post Altech cracks the silicon code: DFS outlines attractive IRR of 34% for higher energy EV batteries appeared first on Stockhead.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…