Energy & Critical Metals

The value of cogeneration in decarbonising Japan

Cogeneration remains a promising technology even for a country like Japan, where it generates 5% of the country’s capacity.

The post The value of cogeneration…

It’s been 141 years since Thomas Edison operated the first modern cogeneration plant on Pearl Street in Cambridge, Massachusetts, and today cogeneration remains a promising technology for many countries.

One such country is Japan, where CHP is responsible for generating 5% of the country’s capacity.

As part of a country-focused series presented by COGEN World, Thomas Smith, president of the Cogeneration World Coalition, and Dr Takao Shinji from the Advanced Cogeneration and Energy Utilization Center of Japan (ACEJ), mapped out the potential for cogeneration in Japan.

Despite the potential, Shinji made it clear that market growth will come down to whether cogeneration makes economic sense and can provide the efficiency and balancing needed for Japan’s grid.

Gas-power CHP is big in Japan

It was after the Fukushima earthquake in 2011 that the Japanese CHP market really began to expand, with installations increasing to ensure the availability of stand-alone power during outages.

Since then, CHP has found a key role, especially in the industrial sector, within which CHP makes up 80% of use cases.

Extreme temperature differences between summer and winter mean Japan relies on CHP for heating and cooling. Furthermore, explained Shinji, the country places great emphasis on energy efficiency and conservation, making CHP critical.

In cities across the country, almost all CHP is driven by gas rather than using diesel engines in an effort to reduce emissions.

Gas-based CHP not only saves energy by producing electricity and utilising waste heat, but Shinji emphasises that CHP also provides much-needed balancing and inertia as renewable generation is increased.

The fact is that gas engine efficiency is high, he added. This makes gas engines the prime mover of the market, with low-carbon fuels and hydrogen, making less of an immediate impact but being considered in future applications.

Market conditions

Japan has about 13GW of operating CHP, according to Shinji, although most commonly used without reverse power. Excess generation is rarely sold back to the utility, due to technical requirements of grid connection and the power price.

The price the utility pays is low making it uneconomic for the generator.

More protection relays are also required to prevent power from flowing back to the grid during an outage, a complicated and expensive installation.

Since overproduction is uneconomic, CHP units are usually smaller and about one-third of peak demand of the facility.

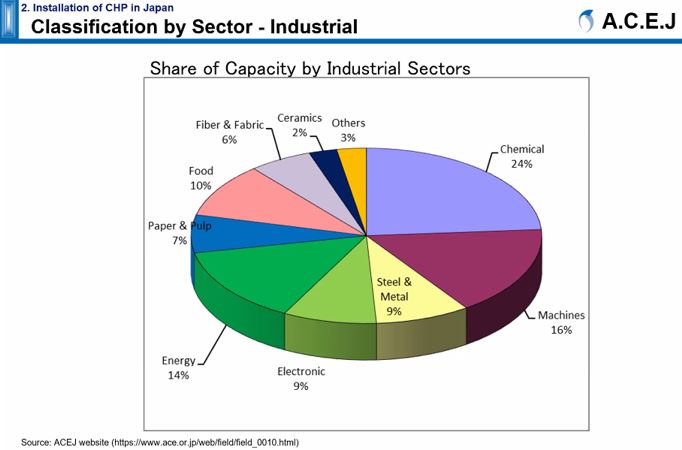

Sectors that consume a lot of heat are most suitable for CHP, said Shinji. In the industrial sector, the chemical and machines sectors make up most use cases of cogeneration in Japan.

CHP adding value

According to Shinji, “energy arbitrage is variable for consumers looking to cut costs and reduce environmental impact”.

He added that in the past, the price of electricity was constant regardless of season, time of day or available supply. However, now Japan operates the Japan Electric Power Exchange… a wholesale market where the price of power varies with supply and demand.

He explained that the balancing market provides ways for producers to increase revenue by using the electricity markets.

However, running CHP during an outage can be complicated, especially without reverse power. The operator of an islanded CHP unit will need to decide what in the facility to prioritise and will need to run the wiring accordingly.

Despite these complications, Shinji referred to two specific case studies where cogeneration is adding a great deal of value. These include the Kiyohara Smart Energy Centre with a 35MW CHP system, consisting of six 6MW gas engines, and the 46 Smart Energy Centre, where waste heat is used from the energy centre and directed under local roads to melt snow and ice in winter. Two 300kW gas engines supply power to a gym, condominiums and a fitness centre.

Micro fuel cell CHP technology

Japan is making great strides in terms of micro fuel cell CHP technology, said Shinji.

The main concept being embraced currently is the high-efficiency Enefarm. Enefarm is a co-generation system that enables both the generation of electric power using a chemical reaction between hydrogen extracted from natural gas and oxygen in the air, and the utilization of heat during power generation to produce hot water.

Shinji explained that the heater has been integrated in a way that if the gas supply is cut, the heater can continue to provide hot water.

Recent development of Enefarm now allows for internet connectivity and for the system to receive weather forecasts. If there is a high probability of an outage caused by, for example, a lightning storm, the Enefarm can disconnect in advance.

A smartphone app is available allowing the system to be controlled and monitored remotely and companies are working to increase energy efficiency and reliability of the system, as well as decrease the number of parts to reduce carbon footprint.

Shinji believes that CHP will get more important in the era of carbon neutrality, with circa 200MW capacity growth expected each year.

However, strict grid codes and a lack of government incentives have hindered progress. A favourable policy landscape is critical, he suggested, to maximising the value of CHP.

The post The value of cogeneration in decarbonising Japan appeared first on Power Engineering International.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…