Energy & Critical Metals

‘Scale, Grade, and Ionic Clay’: Testing proves Alvo Minerals’ Bluebush rare earths project is ionic adsorption clay-hosted

Special Report: Alvo Minerals has surged 25% in early trade after testing proves that the Bluebush project in Brazil is … Read More

The post ‘Scale,…

- Metallurgical testing proves that Alvo Minerals’ Bluebush is a highly sought after ionic adsorption clay-hosted rare earths project

- Not all clay deposits are ionic (rare earths can be leached at ambient temperatures and pressures)

- Recoveries of up to 89% and 86% of MREO’s neodymium and praseodymium achieved at ambient temperatures

- Future test work to optimise recoveries will use samples from follow-up auger and diamond drilling

- Auger and diamond drilling is ongoing across the project

Alvo Minerals has surged 25% in early trade after testing proves that the Bluebush project in Brazil is a highly sought-after ionic adsorption clay-hosted rare earths deposit.

Not all clay rare earths deposits are created equal. The best ones have a substantial ionic portion, which can be ostensibly easily, quickly, and cheaply leached out in a low/zero acid solution.

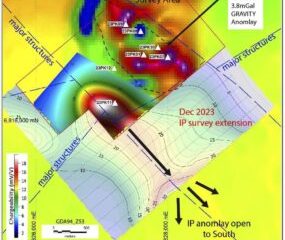

Alvo Minerals (ASX:ALV) 120km2 Bluebush project is on the northern half of the Serra Dourada granite, which also hosts the monster Serra Verde deposit (911Mt at 1,200 parts per million total rare earth oxides) directly to the south.

Serra Verde is the only known Tier 1, ionic clay-hosted REE deposit under construction outside China.

ALV had previously considered Bluebush to be highly prospective for the high value magnet rare earth elements hosted in surficial saprolites, which are typically a clay-rich rock and could potentially be of the highly valued ionic adsorption clay classification.

Auger drilling has certainly proved that the clays are rich in REEs – including MREOs – with one hole returning a 6m intercept grading 2,537ppm TREO including 3m at 3,415ppm TREO (24% MREO).

Diamond drilling is also underway to test the depth profile of the saprolite clay across both the Boa Vista and Sao Bento prospects to improve the company’s understanding of the key saprolite profile.

It’s ionic clay alright!

Initial metallurgical test work on auger samples taken from the Boa Vista and Sao Bento prospects has now proven that mineralisation at Bluebush is indeed ionic adsorption clay-hosted after achieving excellent REE extractions using industry standard ammonium sulphate solution (AMSUL), which is weakly acidic (pH 4).

Recovery rates of high-value MREOs using AMSUL at ambient temperatures achieved the following extractions after just 30 minutes:

- Neodymium – up to 89%, averaging 60%;

- Praseodymium – up to 86%, averaging 57%;

- Dysprosium – up to 53%, averaging 37%; and

- Terbium – up to 69%, averaging 48%.

These are excellent results when one considers that they were achieved in unoptimised conditions.

“This is a significant step forward for Bluebush with the confirmation of ionic clay adsorption hosted mineralisation at both Boa Vista and Sao Bento. The results are outstanding for initial metallurgical testwork with individual samples of MRE’s recovering up to 83%,” managing director Rob Smakman said.

“We have said from when we acquired this exciting project, there were three things we wanted to clearly demonstrate during the due diligence period: scale, grade, and ionic clay (adsorption) mineralisation.

“Our results released to date have demonstrated high grades of TREO and MREO near surface and over broad areas at both Boa Vista and Sao Bento prospects, covering the potential size and grade questions.

“The final, and possibly the most important factor, was establishing the presence of ionic clay adsorption hosted mineralisation. The testwork released today shows this.

“With samples from over 130 auger holes still in the lab, ongoing diamond drilling, regional exploration through handheld auger drilling and the initiation of the Loupe geophysical surveys, we expect there will be plenty to report leading into the end of CY2023 from the Bluebush ionic REE project.”

Future activity

ALV plans to design future metallurgical investigations using samples from the follow-up auger and diamond drilling to improve overall MREO recoveries and develop a more complete understanding of the nature of the clays.

Recoveries are likely to improve further with optimisation of the process.

Meanwhile, the company is continuing diamond drilling across Bluebush with drill core to be saved for any resource estimation and metallurgical sampling purposes in the future.

It will also use the Loupe portable electromagnetic survey system to map the thickness and extent of saprolite/clay horizons to prioritise ongoing exploration.

Auger drilling using its truck-mounted rig is continuing with 210 holes totalling 1,669m completed to date at the project while handheld auger drilling is used on targets in more remote areas.

ALV will also continue soil sampling and mapping towards the middle of the Serra Dourada granite.

This article was developed in collaboration with Alvo Minerals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

The post ‘Scale, Grade, and Ionic Clay’: Testing proves Alvo Minerals’ Bluebush rare earths project is ionic adsorption clay-hosted appeared first on Stockhead.

asx

rare earths

ree

praseodymium

neodymium

terbium

dysprosium

rare earth oxides

diamond

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…