Energy & Critical Metals

Pilbara Minerals and Calix to build and operate demo plant for electric calcination for Li-rich salt

Australian lithium producer, Pilbara Minerals Limited and Australian environmental technology company, Calix Limited, will construct and operate a mid-stream…

Australian lithium producer, Pilbara Minerals Limited and Australian environmental technology company, Calix Limited, will construct and operate a mid-stream demonstration plant in a joint venture.

The project aims to demonstrate the potential to reduce carbon emissions intensity for the hard-rock lithium supply chain via the creation of a high-purity lithium-rich chemical salt (lithium phosphate) using electric calcination that could be powered from renewable energy when available. The project at full production capacity is estimated to produce more than 3,000 tonnes per year of lithium phosphate (Li3PO4).

Market engagement with participants in the battery and chemicals supply chain has encouraged the pursuit of the product and confirmed that it has strong potential to be an improved lithium feedstock for the lithium chemicals industry.

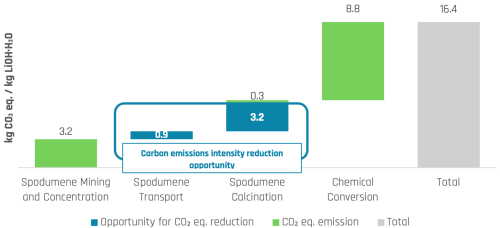

Life Cycle Assessment studies commissioned by Pilbara Minerals have calculated that when using 100% renewable electricity for electric calcination, the carbon emissions intensity of spodumene calcination can be reduced by more than 90% when compared to using coal as the primary source of thermal energy in rotary kiln calcination, and by more than 80% when compared to the use of natural gas.

The assessments conclude that successful implementation of electric calcination on-site at a spodumene mine and concentrator could materially reduce carbon emissions intensity associated with spodumene calcination by more than 3 kg CO2 eq. per kg LiOHᐧH2O when using renewable energy compared to using coal as the thermal energy source in rotary kiln calcination.

Potential reduction in carbon emissions intensity using renewable electric calcination on site compared to shipping spodumene concentrate and processing in a conventional coal-fired calciner for lithium hydroxide production in China. Source: Pilbara Minerals

Potential reductions in carbon emissions are also anticipated from producing a mid-stream product by avoiding the transport of waste associated with spodumene concentrate.

As well as reducing calcination carbon emissions intensity which is one of the most energy intensive steps in the lithium battery materials supply chain, the project also aims to enable greater value extraction from hard-rock lithium assets, by allowing spodumene producers to better utilize mineral resources and move down the battery materials value chain by producing a higher-value intermediate product on-site. This will potentially enable more value to be captured onshore at the resource.

Depiction of a 3.1MW Calix electric calciner for a mid-stream lithium processing demonstration plant. Source: Calix

The strategy of producing a mid-stream product also has the potential to unlock remote hard-rock assets globally that have challenges such as long distances to export infrastructure or customers.

Key objectives of the Project include:

-

to validate Calix’s electric flash calciner in converting spodumene concentrate from

α to β phase. -

to validate calcination of lower grade fine spodumene concentrate which could potentially lead to improved overall lithia recoveries in the spodumene concentrator plant.

-

to validate the potential to use electric flash calcination—capable of being powered by 100% renewable energy when available—to reduce CO2 equivalent emissions intensity in spodumene calcination by >80% when compared to conventional fossil fuel-fired rotary kilns.

-

to generate supporting data to confirm lower capital and operating costs over conventional calcining processes, by utilising electric calcining.

-

to demonstrate an ability to produce a lithium-rich mid-stream product on-site, which significantly reduces the transportation of waste from site and potentially enables more “value adding” at the resource.

-

to enhance Pilbara Minerals’ operational learnings in chemical processing which will be readily transferable at a commercial scale.

-

to produce sufficient volumes of mid-stream product to test market pricing.

To date the JV has been informed at a pilot scale from prior test work that was undertaken in the lead up to making a FID. The Project will now seek to achieve these outcomes at a demonstration scale using a commercial-scale calciner.

Mid-stream demonstration plant location and layout. Source: Pilbara Minerals

The Calix electric calciner designed for the project represents a commercial-scale single tube kiln. Deployment of this technology in a commercial-scale chemical train will comprise multiple units of a comparable scale.

Spodumene concentrate feed will be purchased by the JV from Pilbara Minerals on commercial terms consistent with market pricing.

Pilbara Minerals as manager of the JV will seek to sell all lithium phosphate produced from the demonstration plant on commercial terms to participants in the lithium supply chain through ongoing market engagement which to date has shown strong support for the product.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…