Energy & Critical Metals

Li-Metal successfully produces lithium metal directly from lithium carbonate at Ontario pilot plant

Li-Metal Corp., a developer of lithium metal and lithium metal anode technologies, has successfully produced its first lithium metal at its lithium metal…

Li-Metal Corp., a developer of lithium metal and lithium metal anode technologies, has successfully produced its first lithium metal at its lithium metal piloting facility in Markham, Ontario.

Domestic lithium metal production capacity is essential for the development of a sustainable supply chain for next-generation batteries. Li-Metal’s successful demonstration of lithium metal production from carbonate further advances the its vision to establish North American-based lithium metal production capacity that next-generation battery developers can leverage.

Additionally, this milestone will allow the Company to secure its own supply of lithium metal for its anode production, in order to implement its vertically integrated business model.

We believe we are one of the first internationally to produce lithium metal directly from lithium carbonate at this scale. The ability to produce metal from carbonate is a metallurgical process breakthrough and we are pleased to have accomplished this in Canada.

—Maciej Jastrzebski, co-founder and CTO of Li-Metal

The production of lithium metal directly from lithium carbonate removes the need for corrosive lithium chloride feedstock material which consequently eliminates the production of chlorine gas encountered in conventional lithium metal production processes. This reduces the environmental impact of Li-Metal’s lithium metal production and minimizes the need for costly treatment equipment, enhancing the cost-effectiveness of the Company’s technology.

Li-Metal was recently granted a patent for the production of lithium metal from carbonate (patent CA3179470 issued by the Canadian Intellectual Property Office), which further supports its growth strategy for its sustainable lithium metal business.

Li-Metal plans to continue running piloting campaigns on its pilot-scale process to refine the product quality and process economics in preparation for commercial deployment. This is in parallel to advancing work on the engineering study for a commercial-scale lithium metal facility and exploring opportunities for sale of lithium metal into the next-generation battery industry and conventional lithium metal markets to build a healthy order book for the Company’s businesses.

Currently, more than 90% of the lithium metal produced globally is concentrated in China, according to Benchmark Mineral Intelligence, and Li-Metal continues to progress its plans to commercialize its patented lithium metal production technology to meet the accelerating domestic demand for this material.

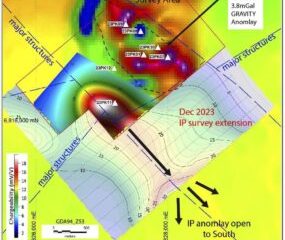

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…