Energy & Critical Metals

Greenstone kicks off Mt Thirsty scoping study, eyes cathode precursor production

Special Report: Greenstone Resources has begun a Scoping Study and Mineral Resource Estimate (MRE) at its Mt Thirsty cobalt-nickel-manganese-scandium JV…

Greenstone Resources has begun a Scoping Study and Mineral Resource Estimate (MRE) at its Mt Thirsty cobalt-nickel-manganese-scandium JV project in WA, incorporating several recently identified project optimisations.

Notably, these include the adoption of High-Pressure Acid Leaching (HPAL) and the addition of a cathode precursor plant to produce a Precursor Cathode Active Material (pCAM).

The Pre-Feasibility Study (PFS) on the project in 2020 employed atmospheric leaching resulting in lower metal recoveries and was completed during a period of subdued commodity prices, which the company says understated the potential of the project to provide “a low-cost, ethical and sustainable source of cobalt and nickel outside of the Democratic Republic of the Congo and Russia.”

“Since early 2020, a number of project optimisation opportunities have been identified which may have a material impact on the Project economics, including the adoption of HPAL and the production of a pCAM product,” Greenstone Resources (ASX:GSR) said.

High value pCAM product

A precursor cathode active material (pCAM) is made of cobalt, nickel, and manganese and is used in the production of cathode materials for lithium-ion batteries, which are commonly used in electric vehicles.

The company says Mt Thirsty is uniquely positioned containing all three of the principal constituents to produce the preferred 811 nickel-cobalt-manganese pCAM product (eight parts nickel, one part cobalt, and one part manganese).

The adoption of pCAM provides the ability to produce a higher value product which typically receives a ~50% pricing premium over the intermediary product (MHP/MSP) the project was previously envisaged to produce.

“This means the production of pCAM has the potential to increase both payable metal content and as a result also increase revenue,” GSR said.

HPAL materially improves recoveries

The other optimisation being investigated is HPAL, the process used to typically extract nickel, cobalt, manganese and scandium from oxide orebodies.

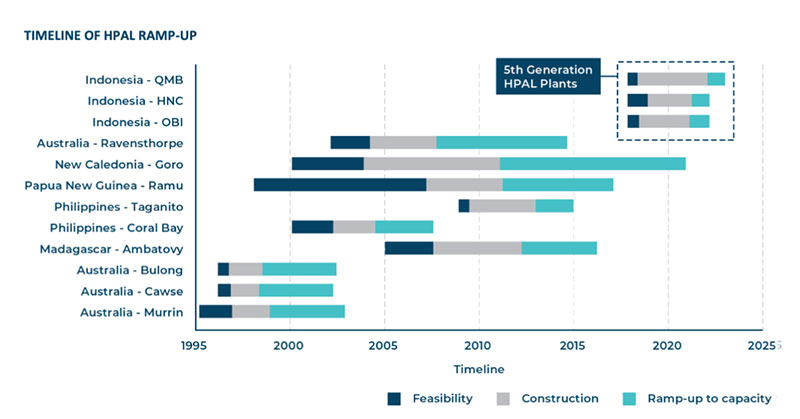

The new fifth generation of HPAL operations in Indonesia are being constructed at US$30-35,000 per annual tonne of nickel, compared to an average of closer to US$100,000 per annual tonne of nickel for the previous generation four plants – and are ramping up to nameplate capacity in less than 12 months.

“The adoption of high-pressure acid leaching at Mt Thirsty is expected to materially improve both cobalt and nickel recoveries, serving to increase the amount of sellable metal and therefore increase life of mine revenue,” GSR said.

“The previously completed pre-feasibility study had elected to utilise atmospheric leaching, however despite extensive metallurgical test work, cobalt and nickel recoveries only averaged 74.3% and 22.3%, respectively.

“Comparable HPAL projects in Australia typically receive cobalt and nickel recoveries of 90.1% and 92.3%, respectively.”

The HPAL test work will also assess the project’s ability to produce a scandium oxide by-product revenue stream.

Updated MRE pending

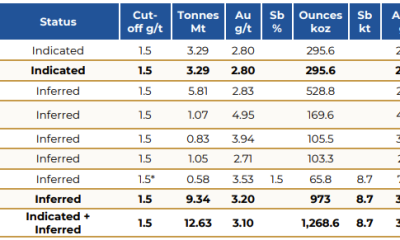

The JV project (50% Greenstone, 50% Conico (ASX:CNJ)) has a current JORC Resource of 26.9Mt at 0.126% cobalt, and 0.54% nickel – which will be updated as part of the scoping study.

“It is expected that the Scoping Study will provide a foundation for the future consolidation and IPO of the Mt Thirsty project later this year, followed by a Pre-Feasibility study, that will target a low-cost, ethical and sustainable source of cobalt and nickel outside of the Democratic Republic of the Congo and Russia,” the company said.

The updated MRE is expected in April 2023 and the updated scoping study and associated project economics are expected in early-mid July 2023.

This article was developed in collaboration with Greenstone Resources Limited (ASX:GSR), a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

The post Greenstone kicks off Mt Thirsty scoping study, eyes cathode precursor production appeared first on Stockhead.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…