Energy & Critical Metals

Georgia Tech researchers develop aluminum-foil-based anodes for all-solid-state Li-ion batteries

A team of researchers from the Georgia Institute of Technology, led by Matthew McDowell, associate professor in the George W. Woodruff School of Mechanical…

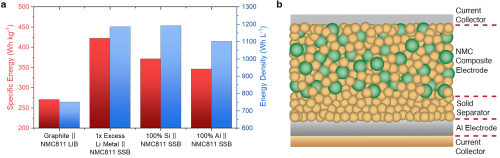

A team of researchers from the Georgia Institute of Technology, led by Matthew McDowell, associate professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering, is using an aluminum-foil-based anode in a solid-state Li-ion battery to create batteries with higher energy density and greater stability. The new battery system is detailed in an open-access paper in Nature Communications.

Metal negative electrodes that alloy with lithium have high theoretical charge storage capacity and are ideal candidates for developing high-energy rechargeable batteries. However, such electrode materials show limited reversibility in Li-ion batteries with standard non-aqueous liquid electrolyte solutions. To circumvent this issue, here we report the use of non-pre-lithiated aluminum-foil-based negative electrodes with engineered microstructures in an all-solid-state Li-ion cell configuration.

When a 30-μm-thick Al94.5In5.5 negative electrode is combined with a Li6PS5Cl solid-state electrolyte and a LiNi0.6Mn0.2Co0.2O2-based positive electrode, lab-scale cells deliver hundreds of stable cycles with practically relevant areal capacities at high current densities (6.5 mA cm−2).

We also demonstrate that the multiphase Al-In microstructure enables improved rate behavior and enhanced reversibility due to the distributed LiIn network within the aluminum matrix. These results demonstrate the possibility of improved all-solid-state batteries via metallurgical design of negative electrodes while simplifying manufacturing processes.

—Liu et al.

a) Theoretical stack-level specific energy (Wh kg−1) and energy density (Wh L−1) comparison of a Li-ion battery (LIB) with a graphite composite negative electrode and liquid electrolyte, a SSB with 1× excess lithium metal at the negative electrode, a SSB with a dense silicon negative electrode, and a SSB with a dense aluminum negative electrode. b) Schematic of a SSB with an aluminum-based negative electrode, SSE separator, and NMC composite positive electrode. The brown spheres represent the SSE and the green spheres represent NMC. Liu et al.

The project began as a collaboration between the Georgia Tech team and Novelis, a leading manufacturer of aluminum and the world’s largest aluminum recycler, as part of the Novelis Innovation Hub at Georgia Tech. The research team knew that aluminum would have energy, cost, and manufacturing benefits when used as a material in the battery’s anode, but pure aluminum foils were failing rapidly when tested in batteries.

Instead of using pure aluminum in the foils, the researchers added small amounts of other materials to the aluminum to create foils with particular microstructures. They tested more than 100 different materials to understand how they would behave in batteries.

The team observed that the aluminum anode could store more lithium than conventional anode materials, and therefore more energy. In the end, they had created high energy density batteries that could potentially outperform lithium-ion batteries.

One of the benefits of our aluminum anode that we’re excited about is that it enables performance improvements, but it also can be very cost-effective. On top of that, when using a foil directly as a battery component, we actually remove a lot of the manufacturing steps that would normally be required to produce a battery material.

—Matthew McDowell

The team is currently working to scale up the size of the batteries to understand how size influences the aluminum’s behavior. The group is also actively exploring other materials and microstructures with the goal of creating very cheap foils for battery systems.

Support is acknowledged from Novelis, Inc. M.T.M. acknowledges support from a Sloan Research Fellowship in Chemistry from the Alfred P. Sloan Foundation. This work was performed in part at the Georgia Tech Institute for Electronics and Nanotechnology, a member of the National Nanotechnology Coordinated Infrastructure (NNCI), which is supported by the National Science Foundation (ECCS-2025462).

Resources

-

Liu, Y., Wang, C., Yoon, S.G. et al. (2023) “Aluminum foil negative electrodes with multiphase microstructure for all-solid-state Li-ion batteries.” Nat Commun 14, 3975 doi: 10.1038/s41467-023-39685-x

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…