Energy & Critical Metals

DOE intends to award up to $37M to advance EV battery recycling, transportation and design

The US Department of Energy (DOE) issued a notice of intent to release a funding opportunity that would provide up to $37 million from Bipartisan Infrastructure…

The US Department of Energy (DOE) issued a notice of intent to release a funding opportunity that would provide up to $37 million from Bipartisan Infrastructure Law (BIL) funding to advance electric vehicle (EV) battery recycling, transportation, and design (DE-FOA-0003120).

As of July 2023, more than 3.9 million plug-in electric vehicles have been sold in the US. With the demand for EVs and stationary energy storage projected to increase the lithium battery market by as much as ten-fold by 2030, it is essential to invest in sustainable, reduced-cost recycling of lithium batteries in support of a secure, resilient, and circular domestic supply chain for critical materials.

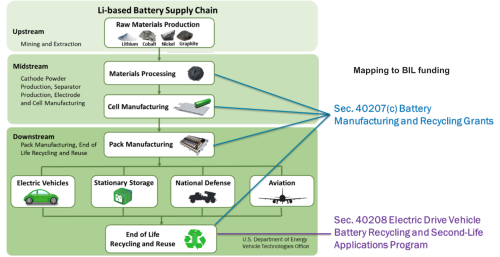

The BIL will invest more than $7 billion in the batteries supply chain over the next five years; this includes sustainable sourcing and processing of the critical minerals used in battery production without new extraction or mining all the way through end-of-life battery collection and recycling.

The anticipated FOA and any related activities support BIL section 40208, Electric Drive Vehicle

Battery Recycling and Second-Life Applications Program aimed at “research, development, and

demonstration of:

-

second-life applications for electric drive vehicle batteries that have been used to power electric drive vehicles; and

-

technologies and processes for final recycling and disposal of the [electric drive vehicle

batteries].

The high-capacity battery supply chain consists of five main steps:

-

raw material production,

-

materials processing,

-

battery material manufacturing and cell fabrication,

-

battery pack

and end use product manufacturing, and -

battery end-of-life and recycling.

The graphic below

shows how these five steps relate to the BIL investments in the battery supply chain.

The anticipated FOA will focus on solutions that reduce the costs associated with battery

recycling through technologies, processes, and product designs that facilitate the transport,

disassembly, and preprocessing of end-of-life electric drive vehicle batteries.

Because the cost

of transportation increases with distance traveled, technologies and processes that can

interface at the point of collection, such as those performed at or with auto recyclers,

dealerships, or automobile mechanic shops, are especially appealing. Also of interest are

technologies or product designs that lower the costs and improve safety associated with the

transport and disassembly of electric drive vehicle batteries including but not limited to:

-

technologies and processes, that improve the safety of end-of-life electric drive vehicle

battery transportation by de-energizing, neutralizing, safely shredding, or otherwise

deactivating the battery; -

product designs that decrease the cost and improve the safety of end-of-life electric

drive vehicle battery packaging; and -

product designs that facilitate the dismantling and separation of end-of-life electric

drive vehicle batteries and battery material.

The anticipated FOA will also address recycling of the electric drive vehicle battery accessory

components. In pursuit of demonstrating the recycling of all battery components, the

anticipated FOA will support technologies and processes for final recycling and disposal of

battery accessory components, including casings and enclosures made from plastics and

polymer composites.

It is anticipated that the FOA would provide approximately $35 million to fund research,

development, and demonstration of transportation, dismantling, and preprocessing of end-oflife electric drive vehicle batteries for recycling at reduced cost, as well as $2 million for

recycling of plastic and polymer electric drive vehicle battery accessory components.

EERE envisions awarding multiple financial assistance awards in the form of grants. The

estimated period of performance for each award will be approximately 3-4 years.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…