Energy & Critical Metals

DOE awards Texas A&M $1M to study fuel performance of Lightbridge Fuel in a NuScale SMR

Lightbridge Corporation, an advanced nuclear fuel technology company, announced that Texas A&M University (TAMU) has been awarded approximately $1,000,000…

Lightbridge Corporation, an advanced nuclear fuel technology company, announced that Texas A&M University (TAMU) has been awarded approximately $1,000,000 by the US Department of Energy’s Nuclear Energy University Program R&D Awards to study the deployment of advanced nuclear fuels in Small Modular Reactors (SMRs).

The project will be conducted over three years and will be funded in its entirety by the DOE, with the goal of bringing collaborative teams together to solve complex problems to advance nuclear technology and understanding.

The study will consist of a comprehensive characterization of the performance of Lightbridge Fuel inside a small modular reactor designed by NuScale Power. Structural Integrity Associates (SI) will perform the thermal evaluation of Lightbridge Fuel in the SMR using its PEGASUS simulation software, a next-generation fuel evaluation and design optimization tool.

The study will generate unique sets of experimental data of friction factor, flow, and heat transfer behavior under normal and off-normal conditions.

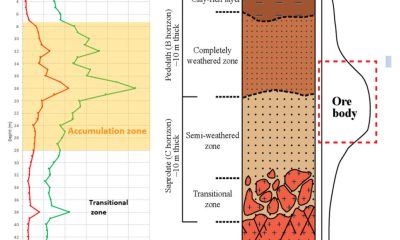

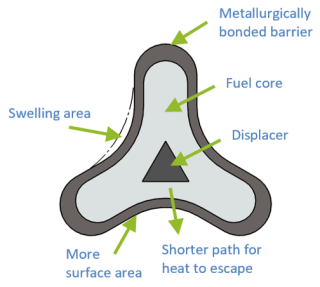

Lightbridge Fuel has a helical multi-lobe fuel rod which increases fuel surface area. At the same time, it reduces the distance it takes heat generated in the fuel rod to reach water, improving fuel coolability. Swelling occurs primarily in the valleys between the lobes to maintain the fuel rod diameter.

Lightbridge Fuel has three components that are metallurgically bonded during the fabrication process. The bonding improves fuel rod integrity, thermal conductivity and eliminates a source of fission product release in the event of a bonded barrier breach. Importantly, this reduces potential radiation exposure for plant workers.

-

The displacer contains burnable poison alloys for neutronics control.

-

The fuel core is uranium zirconium alloy with high thermal conductivity and low irradiation-induced swelling.

-

The metallurgically bonded barrier consists of corrosion-resistant zirconium-niobium alloy with variable thickness to increase protection at the lobe tips.

Lightbridge has secured a long-term strategic partnership with Idaho National Laboratory (INL) in collaboration with the U.S. Department of Energy (DOE). DOE’s Gateway for Accelerated Innovation in Nuclear (GAIN) program has twice awarded Lightbridge to support the development of Lightbridge Fuel. Lightbridge is participating in two university-led studies through the DOE Nuclear Energy University Program at Massachusetts Institute of Technology and Texas A&M University. An extensive worldwide patent portfolio backs Lightbridge’s innovative fuel technology.

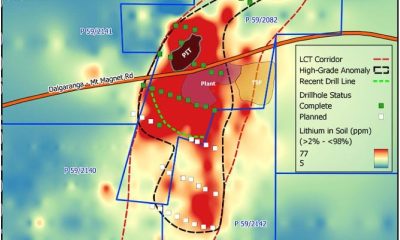

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…