Energy & Critical Metals

CARB Executive Order certifies Toyota’s heavy-duty fuel cell electric powertrain kit as a Zero-Emission Powertrain (ZEP)

Toyota was earlier granted a Zero Emission Powertrain (ZEP) Executive Order (A-014-1170) from the California Air Resources Board (CARB) for its new heavy-duty…

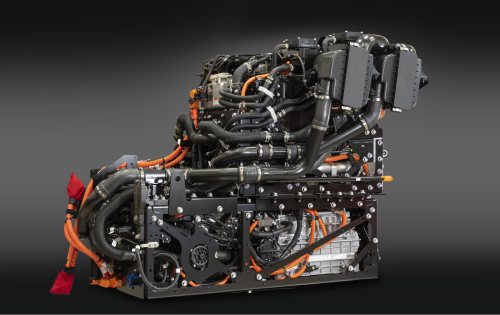

Toyota was earlier granted a Zero Emission Powertrain (ZEP) Executive Order (A-014-1170) from the California Air Resources Board (CARB) for its new heavy-duty fuel cell electric powertrain kit. (Earlier post.) The hydrogen-fueled powertrain kit includes a 200 kWh Li-ion battery; hydrogen fuel storage tanks (58.8 kg capacity, 700 bar), fuel cell stacks, electric motor (224 kW peak, 192 kW steady) and transmission, and offers a viable alternative to traditional diesel powertrains used in commercial goods transportation as companies look to transition their fleets to zero-emission vehicles.

CARB’s ZEP Executive Order certifies that a powertrain complies with CARB regulations for zero-emission powertrains determined to meet specific emissions standards required for sale in California.

OEMs using Toyota’s certified powertrain may also be eligible for other available incentives, such as CARB’s Hybrid and Zero-Emission Truck and Bus Voucher Incentive Project (HVIP), the Clean Truck Fund (CTF) introduced last year by the Ports of Los Angeles and Long Beach, and certain federal incentives.

Toyota’s efforts with hydrogen-powered heavy-duty truck powertrains started with Project Portal back in 2017. Toyota has developed multiple generations of powertrain prototypes during development, such as those found the Alpha and Beta trucks that logged nearly 14,000 miles of testing and real-world drayage operations in and around the Port of Los Angeles.

It was the generation of truck named “Ocean” that showed some of the greatest examples of how hydrogen-based powertrains with fuel cell stacks could be used in real-world applications such as drayage, through a proof-of-concept demonstration at the Port of Los Angeles as part of the Zero-and-Near-Zero Emission Freight Facilities’ “Shore to Store” Project (ZANZEFF). For the project, Toyota worked with Kenworth to develop trucks using an updated prototype fuel cell electric powertrain and deployed 10 Kenworth T680 Class 8 trucks. The 10 trucks served real-world customers via drayage routes, with infrastructure support from Shell, hauling cargo between the Ports of Los Angeles and Long Beach and the LA Basin.

Toyota’s CARB ZEP-certified HD8 FCET Powertrain Kit is now ready for commercialization, with production slated to start for customers later this year at the company’s Kentucky manufacturing plant.

This newest generation of powertrain reflects key learnings and improvements in things like energy efficiency, package size, and more from extensive real-world testing and development from the company’s fuel cell development engineering team.

Fuel cell electric powertrains can be advantageous for heavy- and medium-duty transport when compared to other all-electric options, such as battery electric, as they are often lighter to allow for more payload, and they offer more uptime thanks to fueling times that are much closer to conventional diesel powertrains.

We believe hydrogen will play a significant role in the emissions reduction of heavy-duty transport while not sacrificing the distance, power, or fueling times needed to keep these fleet and individual operators running. Fuel cell technology is scalable, and we believe it will take an increasingly visible and important role in our collective fight to reduce and eliminate carbon as we move towards a hydrogen society.

—Chris Rovik, executive program manager, advanced mobility, Toyota Motor North America

From creating one of the world’s first mass market passenger fuel cell electric vehicle in the Mirai, to applying and scaling the technology now to other applications that can benefit from zero-emissions, including heavy-duty transport, power generation systems, and others, Toyota’s research and development with hydrogen fuel cell technology spans nearly 30 years.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…