Energy & Critical Metals

Airbus becomes strategic partner of DG Fuels for SAF

Airbus has become a strategic partner with DG Fuels (DGF), an emerging producer of sustainable aviation fuel (SAF). DGF’s fuel production system is based…

Airbus has become a strategic partner with DG Fuels (DGF), an emerging producer of sustainable aviation fuel (SAF). DGF’s fuel production system is based entirely on cellulosic waste products, such as wood waste from the logging industry, and renewable energy sources, such as wind and solar power.

The partnership with DG Fuels supports the emergence of a new technological pathway allowing for the production of SAFs from a broader range of waste and residue sources, first in the US with a potential for large-scale production worldwide.

—Airbus CEO Guillaume Faury

DGF’s plant aims to have an initial production capacity of 120 million US gallons (454 million liters) of SAF per year on average, which could save approximately 1.5 million tonnes of CO2 emissions annually from 2026.

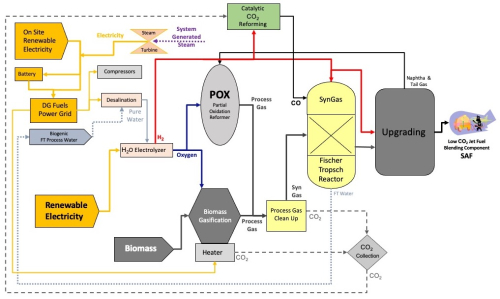

DGF’s fuel production system better utilizes biomass feedstock over conventional biomass-to-liquids projects because of DGF’s use of waste CO2 to make additional fuel. Depending on feedstock carbon content, DGF produces up to 3.6 barrels of biogenic blending component per ton of biomass feedstock compared to most other competitors who achieve about 1.1>1.3 barrel per ton of feedstock, the company says.

DGF’s method modifies the established Fischer-Tropsch system with several mechanisms that will decrease the CO2 life-cycle emissions and reduce the quantity of feedstock required. These changes eliminate the need for carbon sequestration and reduce the system’s feedstock handling costs and complexity.

Source: DG Fuels

The feed-stock reduction is achieved primarily by supplementing the process with oxygen and hydrogen produced by water electrolysis units that are powered by clean wind- and solar-generated electricity. DGF replaces the coal gasification used by others with biomass gasification and natural gas reforming. This simplifies implementation and further reduces new carbon emissions created in the process.

The partnership with Airbus supports DG Fuels’ goal of launching the equity process and reaching a final investment decision (FID) on building DG Fuels’ first SAF plant in the United States. The decision would be expected by early 2024. In this context, Airbus and DGF have agreed for a portion of the production of the first plant to benefit Airbus’ customers.

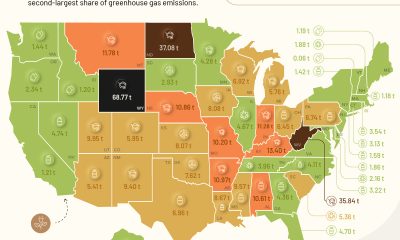

This project is in line with the US government-sponsored SAF Grand Challenge, which aims to reduce costs, improve sustainability and expand domestic SAF production. This national program aims to produce 3 billion US gallons (11.3 billion liters) of domestic sustainable aviation fuel per year, achieving at least a 50% reduction in lifecycle greenhouse gas (GHG) emissions compared to conventional fuel by 2030 and 100% of projected aviation fuel consumption—or 35 billion US gallons of annual production—by 2050.

SAF has been identified as one of the key elements in helping achieve emissions reduction goals. Since 2008, Airbus has acted as an important catalyst in the certification process, demonstration flights, partnerships and policy advocacy of sustainable aviation fuel. In 2016, Airbus became the first aircraft manufacturer to offer customers SAF at delivery flights. Today, aircraft and helicopters leave Airbus delivery centres with SAF onboard from Toulouse and Marignane in France, Hamburg and Donauworth in Germany, Mobile in the US, and most recently Tianjin, China.

Airbus operations and logistics are also carried out with SAF including its fleet of Belugas from 2019. Airbus’ commercial aircraft, helicopters and military aircraft are capable of flying with an up to 50% blend of SAF mixed with kerosene and will be capable of operating with 100% SAF by 2030.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…