Energy & Critical Metals

Researchers develop optimal silicon disulfide production technology for solid-state batteries

Researchers from the Korea Electrotechnology Research Institute (KERI) and Kumoh National Institute of Technology (KIT), have developed a low-cost production…

Researchers from the Korea Electrotechnology Research Institute (KERI) and Kumoh National Institute of Technology (KIT), have developed a low-cost production technology for silicon disulfide (SiS2) for solid-state electrolytes (argyrodite-type) that has potential to accelerate the commercialization of all-solid-state batteries (ASSBs).

The team’s findings from the silicon disulfide study were published as the cover article (open access) in the recent edition of the RSC Journal of Materials Chemistry A.

ASSBs replace the liquid-state electrolytes that transfer ions between the anode and cathode with a solid less prone to fire or explosion. However, there remain many challenges to achieve commercialization, e.g., difficulties in processing and mass production, high material cost, and so on.

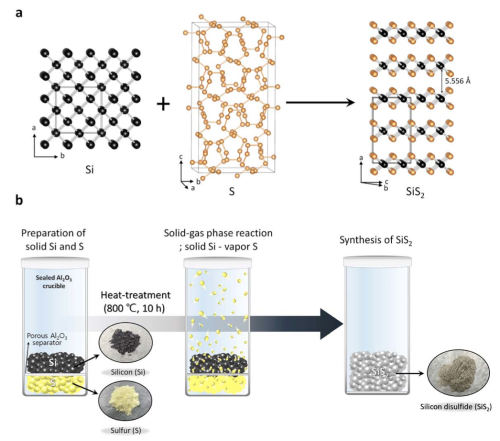

In this study, the team chose silicon disulfide to address these challenges. Adding silicon disulfide to solid-state electrolytes for ASSBs is known to improve ionic conductivity and moisture stability. However, the synthesis of silicon disulfide from sulfur and silicon requires a high reaction temperature, which leads to surges in the vapor pressure of sulfur, making the silicon disulfide production process particularly tricky. For this reason, silicon disulfide is a very expensive material—currently costing about KRW 1.7 million (US$1,300) per 20 grams.

Synthesis of SiS2. (a) Crystal structure of layered orthorhombic SiS2 combining cubic Si and orthorhombic S. (b) Schematic of the solid–gas phase reaction for synthesizing SiS2.

The team succeeded in establishing synthesis conditions by optimizing the arrangement of sulfur and silicon powders and creating a perfectly sealed environment to withstand the vapor pressure of sulfur at 800 degrees of reaction temperature. The quality of the resulting product was comparable to the commercially available products.

The SiS2 nanocomposite, which was fabricated using amorphous carbon in a simple mechanical process, has a high lithiation/delithiation capacity of 1610/1363 mAh g−1, high initial coulombic efficiency of 84.7%, extremely high cycling stability after 800 cycles, and high rate capability.

The team made solid-state electrolytes using their silicon disulfide and found that it had more than twice the ionic conductivity and moisture stability. Also, the optimized process will help simplify the production and reduce production costs.

The team also applied the new silicon disulfide as an anode active material for liquid electrolyte-based lithium-ion batteries and identified the destruction and recovery of layered structures during charging and discharging for the first time.

… the large-scale synthesis method, exceptionally high Li-storage characteristics, and remarkable SSE application of the layered SiS2 make it highly suitable for a variety of applications.

—Nam et al.

Resources

-

Ki-Hun Nam et al. (2023) “Silicon disulfide for high-performance Li-ion batteries and solid-state electrolytes,” Journal of Materials Chemistry A doi: 10.1039/D2TA08877K

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…