Energy & Critical Metals

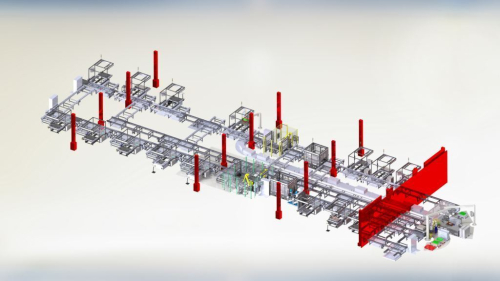

Impact Clean Power Technology unveils visualization of GigafactoryX; 4 GWh/year by 2027

Poland-based battery systems maker Impact Clean Power Technology unveiled a visualization of GigafactoryX—a large-scale battery factory for electric…

Poland-based battery systems maker Impact Clean Power Technology unveiled a visualization of GigafactoryX—a large-scale battery factory for electric vehicles and energy storage which will be launched in the city of Pruszków, near Warsaw. The Li-ion battery systems to be manufactured will include LTO, LFP and NMC technologies.

Its construction will increase Impact’s production capacity to 1.2 GWh in 2024 and more than 4 GWh per year in 2027. The fully automated production line will make it possible to produce a new battery for heavy-duty e-mobility every 11 minutes.

GigafactoryX’s production area will eventually be 16,300 sqm. Among other things, the factory will include a battery testing facility and an advanced research and development center.

Upon completion of the investment in Poland, batteries will be made for various types of electric vehicles, including those serving public transportation, such as e-buses, e-trucks and the railway sector. The plant will also produce energy storage systems designed for the commercial power industry, including for large-scale electricity storage.

The company teamtechnik Production Technology Poland is responsible for the supply and installation of the production line at GigafactoryX. The company, which was acquired by family investment company TDJ in 2020 from the German family company Teamtechnik Maschinen und Anlagen (Teamtechnik MA), specializes in building automated assembly lines for the e-mobility, industrial goods and life science industries.

GigafactoryX production line.

The first phase line has dimensions of 58 by 19 meters and is thus the largest project implementation in the history of teamtechnik Poland for battery systems. Fourteen engineers worked continuously for four months on its mechanical, electrical and automation design.

The flexibility of the line is influenced by the use of a production loop, which allows production to be optimized depending on the type of product being produced. As a result, it enables savings in both space and costs for the investor. The safety of employees operating the line is taken care of by thermal imaging cameras; when an elevated module temperature is detected, a product evacuation procedure is activated.

The teamtechnik solution is also a key element for increasing Impact’s production efficiency. In 2024, the line will enable the production of 16,000 units of battery systems, compared to the company’s current capacity of about 2,500 units. It also delivers reproducible product quality, as it includes full automation of processes such as robotic assembly of individual components, batching, screwing, vision inspection and a range of tests. It will use Bosch Rexroth’s TS7 conveyor system for the first time. Assembly work is scheduled to begin this month.

The batteries for heavy duty e-mobility that will be made at the new plant will be a large-size product, with maximum dimensions of 1400 mm x 1000 mm x 400 mm and weighing up to 500 kg. Production will be based on full product traceability, product management policies in case of non-conformities and their correction or repair. The use of such solutions makes it possible to repair a non-conforming product already on the production line and run it through functionality tests again to get a result that confirms the expected quality.

The factory will be certified to IATF 16949:2016, ISO 45001:2018 and ISO 14001.:2015, ISO 9001:2015, as well as have the 6S system, which addresses workplace maintenance standards.

The commissioning of the first automated production line is scheduled for January 2024.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…