Energy & Critical Metals

Fortum Battery Recycling exploring new hub development in Germany

Fortum Battery Recycling has started to examine the feasibility of installing a production facility for sustainable secondary battery materials in the…

Fortum Battery Recycling has started to examine the feasibility of installing a production facility for sustainable secondary battery materials in the industrial area of Artern, Thuringia, Germany. The black mass facility will be Fortum Battery Recycling’s second hub in Central Europe.

In March, Fortum Battery Recycling started its first commercial operations in Germany, Kirchardt, as the first mechanical processing plant was opened. In April, the company started operating a hydrometallurgical facility in Harjavalta, Finland that is today Europe’s largest closed-loop recycling facility.

The industrial area of Artern/Thuringia is located in the middle of Germany, with short distances to the central battery and automobile companies. The state of Thuringia aims to cover the entire value chain, from basic and applied research to the production of mobile and stationary batteries, and recycling, as one of the few German federal states.

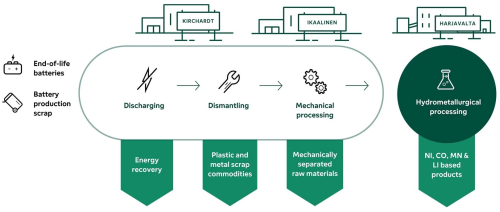

Fortum Battery Recycling’s operations cover all the necessary treatment and production steps at an industrial scale to achieve the highest recycling rates and provide a closed loop for battery recycling along the entire value chain in Europe: pre-treatment services in Kirchardt, Germany, and mechanical process in Ikaalinen, and hydrometallurgical metal recovery in Harjavalta, Finland. The central-European growth plans will help to meet battery manufacturers’ rising demand for recycled battery materials.

Fortum’s low CO2 battery recycling process

We are on a strong growth path, and by 2030, we aim to develop our recycling capacity to handle over 200 000 tonnes of battery waste and aim to open two more hydrometallurgical facilities in Europe and some seven mechanical units producing black mass for the hydrometallurgical sites. We want to help the entire industry produce more sustainable batteries in Europe.

—Tero Holländer, Head of Business Line, Batteries, Fortum Battery Recycling

As a clean energy company, Fortum has been providing waste and recycling services since 2016 and has expertise in the management of both hazardous and difficult waste streams. Fortum’s battery recycling technology is backed by in-house research and development, and the company is continuously exploring opportunities to expand its recycling capacity in Europe.

In March 2023, Fortum Battery Recycling started EV battery recycling operations in Kirchardt, Germany. With the facility in Germany, Fortum is able to offer its services for the collection and processing of end-of-life batteries and production scrap close to central European customers. The hub in Germany can pre-treat more than 3,000 tonnes of batteries per year and is connected to the Harjavalta site where the hydrometallurgical process takes place.

Fortum Battery Recycling is part of the Fortum portfolio. Fortum Battery Recycling is a specialist in recycling of valuable metals in ev batteries. It’s low-CO2 battery recycling solution makes it possible to recycle over 80% of the battery with 95% of the valuable metals contained in the battery’s black mass to be put back into circulation.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…