Economics

Digitally transforming water

Australian Mining sat down with Xylem to discuss its Ripple Effect white paper and the importance of taking a holistic …

Australian Mining.

Australian Mining sat down with Xylem to discuss its Ripple Effect white paper and the importance of taking a holistic approach when adopting digital change.

Global technology providers such as Xylem are playing a critical role in facilitating the digital evolution of the Australian resources industry.

Parallel with its reputation as a key original equipment manufacturer (OEM) and solutions provider for water applications in the sector, Xylem is ushering in new digital innovations and ideas that are challenging the status quo.

The company’s commitment to digitalisation is embodied in its recently released Ripple Effect white paper, something Xylem Vue digital solutions manager Kevin Tasker said forms part of the company’s broader mission: “Let’s Solve Water”.

“Everything we do within the home, in industry, on a mine site, involves water and treating water – it’s a whole ecosystem,” Tasker told Australian Mining.

“So the idea of Ripple Effect is to look at different organisations and consider, ‘How can we source, treat and use water in the most sustainable and environmentally conscious way possible?’”

In preparing Ripple Effect, Tasker he worked with customers on reducing their carbon footprint, which included looking at amenable technologies from source to treatment.

“In one instance, we looked at smart metering which can help to identify leaks,” he said.

“So it’s about combining technologies in the market to be more sustainable and achieve better efficiencies.

“This is the ethos of Ripple Effect and being able to communicate with utilities both large and small to say, ‘These are the steps that you can take. This is the foundation work that you can do’.

“Then we can get that ‘ripple effect’ through their operations.”

The Ripple Effect insights are particularly pertinent to the resources industry, given the range and scale of water applications on a mine site.

Tasker said there are opportunities for mining companies to harness the ‘ripple effect’ thinking when carrying out closure and rehabilitation activities.

“I have a personal interest in mine rehabilitation, something which the mining industry must be vigilant about,” he said. “From a regulatory point of view, mining companies are facing increased scrutiny regarding that final transition from operating mine to mine closure.

“And many mining companies only know what they know in terms of what’s possible within a particular part of the water lifecycle process. They don’t always have this overarching understanding of, ‘How can I optimise different parts of operations and maintenance, and how do I then transpose that into the lifecycle?’”

This is where Xylem’s end-to-end insight and offerings can encourage mining companies to consider their operations holistically and understand the importance of proactive water management as part of this.

“Miners less vigilant about their environmental management will take off the topsoil, push it to one side and use it later,” Tasker said.

“In doing that, they are completely degrading the soil. So you have this opportunity where there may be an abundance of groundwater, even in the driest places, and they can potentially use that to help irrigate and maintain soil health, biomass and biodiversity.”

Xylem can play an important role in this process by not only connecting the necessary water pumps, but by integrating an end-to-end process that harnesses the company’s digital software and expertise.

“Operators don’t have to be worried about, ‘I’ve got to come up with this whole digital solution’,” Tasker said. “They can connect some initial steps to achieve a goal rather than being concerned by an immediate upfront large-scale digitisation commitment.”

If a miner has already taken the steps to deploy siloed digital processes, Xylem can also help connect the dots.

“If you can identify a few digital processes that are already in place, connect them and create an optimisation, that can create momentum – especially for smaller mine sites – for further digital optimisation and improved water management processes,” Tasker said.

“Through our agnostic approach, Xylem can provide solutions to complement any existing digital technology, hardware, infrastructure or strategy. We understand the importance of working with people, processes and technology in achieving new operational optimisations.”

Tasker used an example of an existing mining customer benefiting from Xylem’s holistic digital offerings. In this case, the Australian mining company accesses water through a desalination plant.

“The customer runs its desalination plant at full capacity to make sure they get the right water quality, but what they’re not doing is maybe optimising some processes before that in terms of dewatering or filtering before the water is treated,” Tasker said.

“So we’ve been gathering information about their process. This includes analysing existing SCADA (supervisory control and data acquisition) systems, pumps, flow and retention time and from that they will be able to reduce costs for the maintenance of the desalination plant.”

Tasker said the customer can also realise secondary benefits from Xylem’s support. A more efficient and less exhaustive water treatment process can also reduce carbon emissions and fuel costs.

And this case study is not only relevant to the water treatment processes of a desalination plant, with all other water applications in the mining industry able to benefit from Xylem’s expertise and offerings.

Today’s inflationary pressures are affecting bottom lines, and that means mining companies are scrutinising expenditure more than ever.

In the wake of such economic difficulties, Tasker said mining companies must build more resilience into their business.

“We look at the past to plan the future and when we look at growth, COVID was obviously a big challenge to that, and immigration fell off, meaning less people were coming to Australia,” he said.

“So the factors driving decision-making are changing, and companies need to build in more resilience into their business.

“Traditionally, resilience has meant putting in extra infrastructure, ‘We’ll put in extra tanks, a reservoir or another treatment plant’, but we can’t do that anymore. The money is simply not there to do that.

“First of all, you have to know how your system or process is operating and what that may look like as a digital system. Optimal placing of sensors into a system or process drives data capture and data model creation while offering a far better understanding into its performance and capacity.

“This digital foundation then allows the use of machine learning and AI to identify optimisations opportunities in the form of recommendations or ultimately a pathway to dynamic control of operations.”

Tasker said many mining companies understand their digital strategy and framework in some, way, shape or form, but not all are necessarily implementing it well as they could be.

“A lack of a holistic digital overview, gaps in process data combined with demarcated silos of operational responsibility makes the implementing of ‘digital intelligence systems’ challenging but not impossible,” Tasker said.

“Ironically, the impacts of global geopolitical instability, skyrocketing costs in the global supply chains, coupled with societal demands for greenhouse gas reductions and decarbonisation of the mining industry may have accelerated water as the element to meet these resilience challenges.

“Xylem’s approach to efficient use water throughout the whole mining process and lifecycle is to help our customers find digital opportunities to continually improve their performance not matter how big or small. “

Digitalisation is offering mining companies insight and data access on a new scale, but this represents something of a catch-22: more inputs don’t always lead to greater operational productivity, safety and sustainability.

It’s the miners that holistically embrace digitalisation that are best off, and global technology providers such as Xylem are playing a critical role in facilitating this thinking.

This feature appeared in the September 2023 issue of Australian Mining.

Argentina Is One of the Most Regulated Countries in the World

In the coming days and weeks, we can expect further, far‐reaching reform proposals that will go through the Argentine congress.

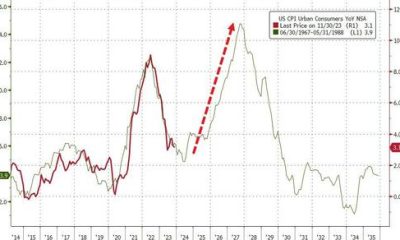

Crypto, Crude, & Crap Stocks Rally As Yield Curve Steepens, Rate-Cut Hopes Soar

Crypto, Crude, & Crap Stocks Rally As Yield Curve Steepens, Rate-Cut Hopes Soar

A weird week of macro data – strong jobless claims but…

Fed Pivot: A Blend of Confidence and Folly

Fed Pivot: Charting a New Course in Economic Strategy Dec 22, 2023 Introduction In the dynamic world of economics, the Federal Reserve, the central bank…